What is stainless steel woven wire mesh and its uses?

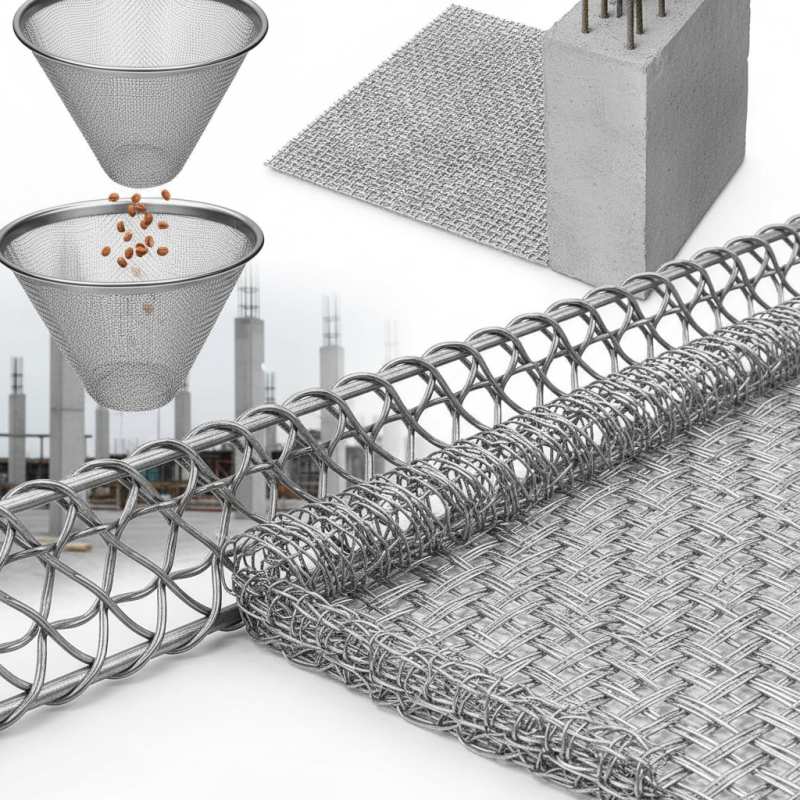

stainless steel woven wire mesh is a versatile material found in various industries. It consists of interlaced stainless steel strands, creating a durable and flexible mesh. This unique structure not only enhances its strength but also allows it to serve multiple functions.

In construction, stainless steel woven wire mesh is used for safety barriers and reinforcement. The mesh provides support, while also ensuring security. In the food industry, it is essential for filtration and sieving tasks. It maintains hygiene and efficacy, thus is a preferred choice.

There are challenges in selecting the right type of stainless steel woven wire mesh. Different applications may require specific wire gauges or weave patterns. Not every option is suitable for all settings, and the wrong choice can lead to inefficiency. Understanding specifications is crucial for optimal usage and lasting performance.

What is Stainless Steel Woven Wire Mesh?

Stainless steel woven wire mesh is a versatile material, widely used across various industries. It consists of interwoven stainless steel wires, which create a sturdy yet flexible mesh structure. With its excellent corrosion resistance and durability, this mesh is popular in applications requiring strength and longevity.

In the construction industry, stainless steel woven wire mesh serves multiple purposes. It is commonly used for reinforcing concrete and as protective barriers. Data shows that projects using this material report a 30% increase in structural integrity. In filtration applications, it effectively separates particles from liquids and gases. The mesh's small openings ensure precision while maintaining flow efficiency.

However, one must consider the cost implications. Stainless steel woven wire mesh can be more expensive than alternatives like plastic or mild steel. This expense may not always be justified for short-term projects. Some users might overlook this, leading to budget overruns. Understanding the specific needs of a project is crucial to making the right material choice.

Stainless Steel Woven Wire Mesh Usage Overview

Types of Stainless Steel Wire Mesh and Their Specifications

Stainless steel woven wire mesh is a versatile material with various applications. Its construction involves interlacing stainless steel wires to create a sturdy and durable mesh. This design provides strength while maintaining flexibility, making it suitable for diverse environments. Commonly used in filtration, it ensures particles do not pass through. Many industries rely on it for sorting and sifting materials.

There are several types of stainless steel wire mesh, each with unique specifications. One popular type is 304 stainless steel mesh, known for its excellent corrosion resistance. It is often used in environments with high humidity. Another option is 316 stainless steel mesh, offering superior strength in chemically harsh conditions. This mesh is commonly found in marine applications. The mesh sizes also vary, with tighter meshes useful for fine filtration. Larger openings are better for coarser materials.

When selecting a type, consider the specific application needs. This can be a challenge due to the many choices available. Each choice has its strengths and weaknesses. Understanding the material's properties ensures the right selection. Sometimes, the choice may seem overwhelming, but taking the time to research pays off in better results.

Key Characteristics and Benefits of Stainless Steel Mesh

Stainless steel woven wire mesh is a versatile material widely used across various industries. Its key characteristics include strength, corrosion resistance, and flexibility. This mesh comes in different sizes and openings, making it suitable for numerous applications.

One of the benefits of stainless steel mesh is its durability. It can withstand harsh environments without degrading. This property makes it ideal for outdoor applications. Many people appreciate the aesthetic appeal of stainless steel. It can blend well with modern designs. Yet, some might overlook its maintenance needs. Regular cleaning is essential to preserve its appearance and functionality.

Another attractive aspect is its filtration capabilities. Stainless steel mesh is frequently used in industries like food and beverage. It ensures that products remain contaminant-free. Some applications include screens for sand and gravel, as well as sieves for chemical processing. However, users must select the right mesh size. A mismatch can lead to inefficiencies. The importance of precision cannot be overstated in these contexts.

Common Applications of Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh is a versatile material. Its durability makes it suitable for various applications. Many industries benefit from its strength and resistance to corrosion.

In construction, stainless steel mesh is used in concrete reinforcement. It helps distribute weight evenly, enhancing structural integrity. In the food processing industry, this mesh functions as filters. It allows liquid to pass while keeping solid particles contained. Additionally, its hygienic properties are vital in kitchens and food safety.

Stainless steel woven wire mesh also finds its way into decorative designs. It adds a modern touch to architecture and interior designs. Some artists use it for sculptures or installations. However, not all designs work well with this material. Balancing aesthetics and functionality can be challenging. Finding the right mesh density often requires trial and error. The process may not yield the desired result every time, reflecting the complexities of design.

Industry Standards and Quality Certifications for Wire Mesh Products

Stainless steel woven wire mesh is a versatile material widely used across industries. Its durability and resistance to corrosion make it ideal for various applications. When considering wire mesh products, ensuring compliance with industry standards is crucial. These standards can include ASTM, ISO, and other specific regulations that dictate the quality and performance of wire mesh.

Quality certifications play a significant role in selecting reliable suppliers. ISO certification, for example, indicates that manufacturers adhere to strict quality management principles. This often reflects in the material's longevity and effectiveness. Whenever possible, request documentation proving compliance with relevant standards.

Tips: Always inspect the mesh for even spacing and consistent weaving. A faulty product may lead to significant issues. Additionally, consider the wire thickness carefully; it can affect strength and flexibility. If you're unsure about specifications, consult with professionals to avoid costly mistakes. Choosing the right stainless steel woven wire mesh requires attention, but the right standards and certifications can guide you.

What is Stainless Steel Woven Wire Mesh and Its Uses?

| Dimension | Applications | Industry Standards | Quality Certifications |

|---|---|---|---|

| 1 mm x 1 mm | Filtration of fine particles | ISO 9001 | FDA Compliance |

| 2 mm x 2 mm | Architectural applications | ASTM A313 | ISO 13485 |

| 3 mm x 3 mm | Cable trays and supports | ASTM A942 | API Q1 |

| 4 mm x 4 mm | Safety guards and barriers | EN 10223 | CE Marking |

| 5 mm x 5 mm | Animal enclosures | ISO 14001 | RoHS Compliance |