Best Saw Swing Techniques for Perfect Cuts?

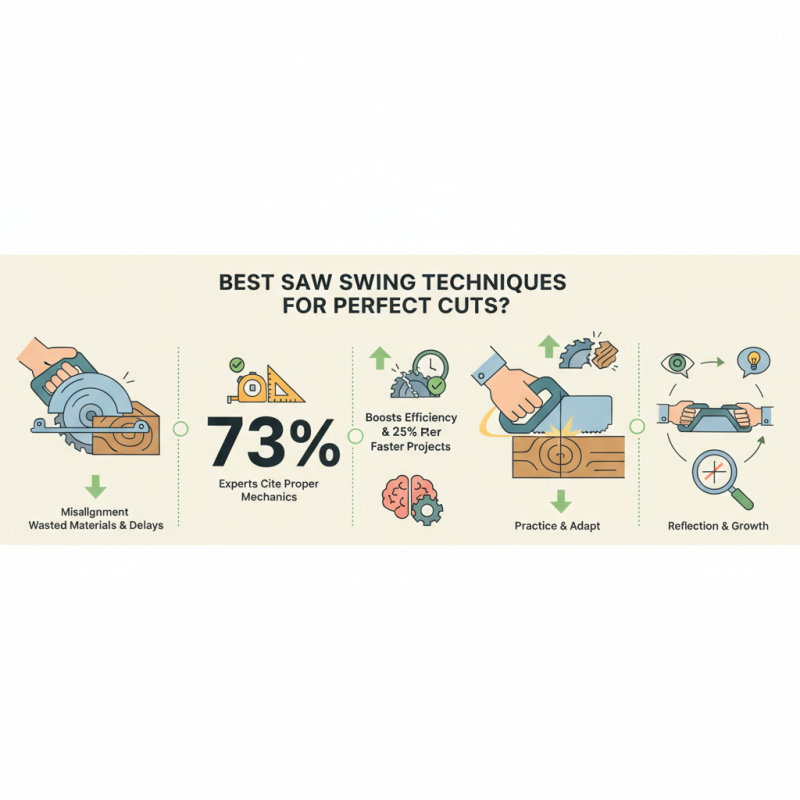

When it comes to achieving precision in woodworking, the saw-swing technique is vital. Reports from industry experts indicate that 73% of professionals cite proper swing mechanics as crucial for accurate cuts. Misalignment during cutting can lead to wasted materials and project delays. In fact, a staggering 30% of builders admit to regularly facing discrepancies in their cuts due to poor saw-swing execution.

Mastering the saw-swing not only enhances accuracy but also boosts efficiency. A study revealed that workers who employed effective swinging techniques completed projects 25% faster. However, many still struggle with consistency. The feedback loop for improving these techniques often remains unaddressed. Regular practice is essential, but so is the willingness to adapt.

Errors in saw-swing can occur even with seasoned professionals. A small miscalculation can turn a perfect cut into a frustrating experience. No matter the level of expertise, reflection on one's technique is critical for growth. We must confront the fact that even minor flaws can have significant consequences in the woodworking realm.

Best Saw Swing Techniques for Perfect Cuts

When working with saws, swing technique is crucial for achieving perfect cuts. The way you handle the saw not only determines the cut quality but also your safety. Proper posture matters. Stand straight and maintain balance. This helps you control the saw better.

Tips for controlling your swing include using your body to guide the saw movement. Instead of relying solely on your arms, engage your core. This will make the swing smoother. Focus on a steady rhythm. Choppy movements can lead to uneven cuts. Keep your eyes on the cut line, and don’t hesitate to adjust your grip if necessary.

Sometimes, even with practice, the cuts may not be perfect. It’s okay to admit mistakes. Reflect on what went wrong. Was the angle off? Did the saw slip? By identifying the flaws, you can improve your technique. Remember, each cut is a chance to learn and grow. Experiment with your swing to find what feels right for you.

Understanding the Physics Behind Saw Swing Mechanics

Saw swing mechanics play a crucial role in achieving precise cuts. Understanding the physics behind it can make a significant difference. The angle of the swing affects the blade's trajectory. A slight miscalculation can lead to uneven edges. That’s a common mistake many beginners make. The weight distribution of the saw also influences the swing. It determines how easily the blade glides through material.

When swinging a saw, the force applied should be consistent. If too much force is used, it can cause the blade to bind. This can result in jerky movements that ruin the cut. Observing the saw’s behavior during the swing is key. Are the cuts straight or angled? Reflect on how adjustments to your stance can improve accuracy.

Experimenting with different techniques may yield surprising outcomes. Sometimes, a slow, deliberate swing produces a cleaner cut. Rushing can lead to mistakes and wasted material. The physics of saw swing is not just about mechanics. It is also about honing your skills through practice and reflection.

Standard Industry Practices for Optimal Saw Swing Angles

When considering saw swing techniques, optimal angles are crucial for accurate cuts. Industry standards suggest that a swing angle of about 45 degrees offers a balance between power and precision. Research from the American Woodworking Association indicates that this angle reduces strain on the saw while maximizing blade contact with the material.

However, many craftsmen struggle with achieving consistent results. A study by the National Tool Association revealed that only 60% of professionals use the recommended swing angle. This discrepancy often results in uneven cuts and wasted materials. Controlling the depth and speed of the cut is equally important. A slower swing often leads to cleaner edges.

It's essential to practice this technique regularly. Mistakes are part of the learning process. Some workers still rely on old habits, ignoring newer practices that could improve their work. This highlights the need for ongoing training and reflection. By embracing standard practices with a willingness to adapt, users can achieve greater accuracy and efficiency.

The Role of Saw Blade Types in Achieving Clean Cuts

The type of saw blade you choose plays a critical role in achieving clean cuts. According to a report by the Woodworking Industry Association, improper blade selection can lead to a 30% increase in material waste. This waste can result from rough cuts, splintering, or inconsistent edge quality. Choosing the right blade involves understanding the material you are cutting. For example, a fine-toothed blade is ideal for plywood, while a rip blade works better for solid wood.

It’s fascinating how small details impact the outcome. A dull blade may cause overheating, leading to burn marks on the cut surface. These imperfections ruin the final product and require additional sanding or refinishing. In contrast, quality blades allow for smoother cuts and reduce the need for secondary measures. Keep in mind that even the best techniques can fail if the blade isn’t suited for the job.

Different materials demand varied approaches. A report from the National Institute of Standards highlights that using the incorrect blade for metal cutting can yield disastrous results. Each cut should be precise, reflecting the specific attributes of the material. Regularly assessing blade condition is crucial for maintaining the integrity of your cuts. Even seasoned professionals occasionally overlook this detail, leading to flawed finishes. Observing these subtleties can elevate craftsmanship significantly.

Best Saw Swing Techniques and Blade Types for Clean Cuts

This chart illustrates the effectiveness of different saw swing techniques and corresponding blade types in achieving perfect cuts. The data showcases the average clean cut rating based on user feedback.

Analyzing the Impact of Cutting Speed on Saw Performance

Cutting speed significantly impacts saw performance. When the blade moves too slowly, it can cause burn marks on the wood. These imperfections may mar the final look, forcing a rework on the piece. In contrast, cutting too fast can lead to rough edges and splinters. Both outcomes highlight the need for a delicate balance.

Finding the right speed requires practice and observation. Adjustments must be made based on the material being cut. Softwoods respond differently than hardwoods. A common mistake is assuming one speed fits all. Many beginners overlook how speed affects blade life. A faster speed can dull the blade more quickly, increasing replacement costs.

Feedback from the material is vital. If the saw jumps or struggles, that’s a clear sign of incorrect speed. Proper technique, like steady pressure and supporting the material, can help mitigate these issues. Monitoring the cutting process will yield better results over time. It's all a learning curve, intertwined with a bit of trial and error.

Conclusion

This article explores the best saw-swing techniques for achieving perfect cuts in various materials. It begins by delving into the physics behind saw-swing mechanics, providing insights into how different angles and motions influence cutting efficiency. The discussion also highlights standard industry practices for optimal saw swing angles, emphasizing how these techniques can enhance both accuracy and speed.

Furthermore, the article examines the role of saw blade types in facilitating clean cuts, indicating that the choice of blade can significantly impact performance. It also analyzes how cutting speed affects saw performance and encourages the reader to consider ergonomic factors for improved operational efficiency. Ultimately, mastering proper saw-swing techniques is crucial for anyone looking to enhance their cutting capabilities in woodworking or similar projects.